INSTALLATION PROCESS

The following is a summary of how the AHRENS process works.

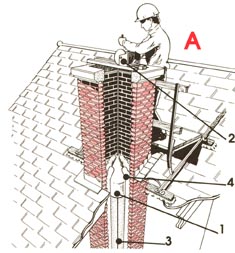

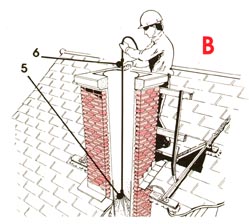

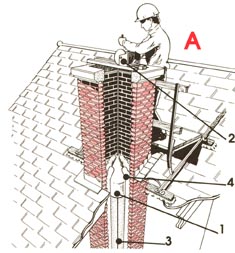

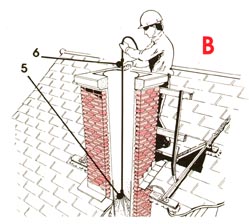

Illustrations A and B will help you visualize the step-by-step procedure.

(KEY TO ILLUSTRATIONS : 1. Vibrating

Bell ; 2. Hand Winch ; 3. Cord to Control Box ; 4. First Liner Mix ; 5.

Second Liner Mix ; 6. Second Liner Applicator.)

FIRST

LINER INSTALLATION FIRST

LINER INSTALLATION

- A correctly sized steel bell is lowered down the flue on a steel cable

- attached to a hand winch set on top of the chimney.

- The AHRENS zero slump first liner mix is poured down the flue to cover

the bell.

- Once the bell has been covered with mix, the vibration placement of

mix starts. Each bell houses a vibrator and the intensity of the vibration

is adjusted from the control box.

- As vibration continues, the bell is slowly winched up through the

mix and the process is repeated until the bell reaches the top of the

chimney.

GLAZE-SETtm APPLICATION (NOT

SHOWN)

- Immediately after the first liner installation, Glaze-Settm

is sprayed on the flue wall with a portable sprayer.

- Minutes later the first liner is ready for the second liner installation.

- If Glaze-Settm is used, it makes the AHRENS system a one-day

process.

SECOND

LINER INSTALLATION (Ill. B) SECOND

LINER INSTALLATION (Ill. B)

- After the first liner has properly set, a foam rubber applicator is

positioned in the top of the flue.

- The second liner mix is poured over the foam rubber applicator and

the applicator is lowered down the flue - or -

- The second liner can be applied with a sprayer.

- The glaze-like second liner is absorbed into the first liner and leaves

a thin coating on the entire flue surface including horizontal openings

at thimble and cleanout door locations.

|

FIRST

LINER INSTALLATION

FIRST

LINER INSTALLATION SECOND

LINER INSTALLATION (Ill. B)

SECOND

LINER INSTALLATION (Ill. B)