|

|

|

| 2-LINER PROCESS | ||

THE

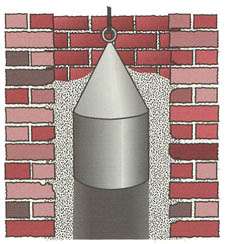

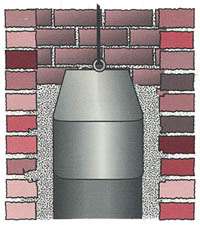

FIRST LINER STRENGTHENS AND INSULATES THE

FIRST LINER STRENGTHENS AND INSULATESThe first liner strengthens as a result of the special masonry mixture being mechanically forced horizontally into your existing chimney walls. The first liner fills every crack and crevice creating an interlocking bond. The excellent insulating effect and proper flue sizing of this liner keeps flue gases warm, reducing condensation no matter what fuel is burned. |

||

THE

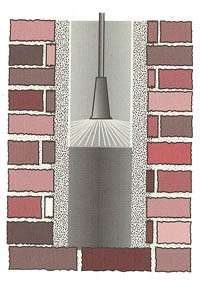

SECOND LINER SEALS AND PROTECTS THE

SECOND LINER SEALS AND PROTECTSThe second liner cures to a thin, hard, glaze-like finish that seals and protects the first liner. This resists absorption of harmful acids or moisture. Because the second liner is very thin, it heats up quickly, minimizing condensation. Each second liner is created in a single pour - no matter what the chimney height or diameter. That means there are NEVER any seams to break, joints to split, tile to crack or metal to rust. |

||

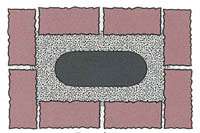

OBLONG

SHAPED FLUES OBLONG

SHAPED FLUES  The Ahrens System is not limited to round flues only. Rectangular chimneys sometimes require an oblong-shaped flue. Your Ahrens dealer has access to hundreds of oblong shapes to assure proper sizing for your appliance or fireplace. |

||

|

||

| © 1997-2008 AHRENS Chimney Technique Inc. | All Rights Reserved e-mail : ahrenschimney@qwestoffice.net

|

||