|

04555/AHR  |

|

| AHRENS 2-LINER PROCESS | ||

THE

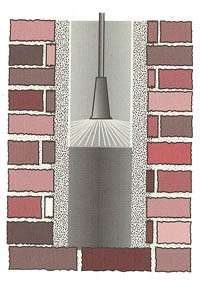

FIRST LINER STRENGTHENS AND INSULATES THE

FIRST LINER STRENGTHENS AND INSULATESA correctly sized steel form (bell) is lowered down the chimney with a winch. The special first liner material, mixed to a zero slump consistency, is poured down the chimney to cover the bell. When winching begins the mix is horizontally compacted into the chimney walls by the wedging effect and vibration of the bell. The first liner mix forms around each brick and fills deteriorated mortar joints. This process is continued as the bell is winched up the chimney to create a continuous liner which is properly sized, insulated and that strengthens the existing chimney. |

||

THE

SECOND LINER SEALS AND PROTECTS THE

SECOND LINER SEALS AND PROTECTSThe second liner is a thin protective glazing that cures to a very hard, acid resistant finish. The second liner can be applied with a spray system or by pouring the material on top of a foam applicator which is then lowered down the flue. The second liner is absorbed into the surface of the first liner and coats the entire flue surface. |

||

|

||

| © 1997-2008 AHRENS Chimney Technique Inc. | All Rights Reserved e-mail : ahrenschimney@qwestoffice.net  |

||