SEVEN

DECADES OF EXPERIENCE

Paul Ahrens first applied his imagination to the development

of new masonry chimney technology in 1924. Since that start, nearly

75 years ago, the family owned company has grown to become the largest

manufacturer of chimney components and relining systems in Europe.

Today AHRENS has many locations in Germany,

Austria, Switzerland and the United States that have installed over

1,000,000 chimney systems. In addition to having developed leading

technology in chimney reconstruction, AHRENS has become the major

manufacturer of concrete chimney accessories.

Seven decades of AHRENS research and

development have produced a complete chimney product line that reflects

the German attention to detail, simplicity of application and insistence

on quality.

TECHNICAL SERVICE

AND SUPPORT

We have a knowledgeable staff on hand, waiting to

analyze your situation and help you arrive at the best solution possible

without obligation. We'll make sure you get our full support from

the planning process through installation.

AHRENS has available the following

professional evaluation and consultation services :

- Video Inspections

- Computer Sizing Analysis

- Specification Assistance

- Special Mix Design

- Steel Reinforcement Design

PRODUCT CAPABILITIES

The AHRENS U.L. Listed product is for low heat type

chimneys with a maximum continuous appliance outlet flue gas temperature

of 1000 F. (538 C.) listed in Column I & II of the NFPA 211 Chimney

Selection Chart.

Appliances such as but not limited to

:

- Residential Heating Appliances

- Commercial Heating Appliances

- Fireplaces

- Steam Boilers

- Dual Fuel Appliances

Other Applications :

- High Temp-to 3000 F. (Special

Material) NFPA 211 Column III, IV & V

- Historical Projects with

specially designed mixes

- Seismic & hurricane reinforcing

- Vertical shaft repair (Non-Chimney)

|

CHIMNEY'S

NEED FOR REPAIR

As masonry chimneys age, the elements take their toll.

If caught in time, the exterior of the chimney can usually be preserved

by using techniques such as tuckpointing.

But, perhaps the worst enemy of masonry

chimneys is the deterioration from within. Acidic condensation created

in the combustion process can cause chimney damage that is not always

visible until it is too late. Airborne pollutants can combine with

the natural by-products of combustion to form these acidic and corrosive

exhausts which "eat" away at the masonry.

As outdated heating systems are replaced

by newer, more efficient systems, the problem is multiplied. Venting

higher efficiency units into large unlined chimneys produces more

acidic condensation and increases damage caused by freeze/thaw cycles.

The alternative for large oversized flues is to increase the amount

of heat that goes up the chimney so condensation does not occur. This

alternative naturally has a negative effect on appliance efficiency

and cannot be considered.

Regardless of the cause, if this deterioration

is ignored, there will eventually be only one solution, tearing the

chimney down and rebuilding. AHRENS offers a better approach!

THE SOLUTION

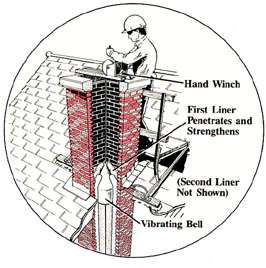

AHRENS Chimney Technique is a unique two liner system

for lining or relining masonry chimneys installed only by trained

authorized AHRENS dealers. In chimneys old and new the AHRENS system

will provide the following benefits regardless of the type of fuel

being burned.

- Properly sizes the flue to the

appliance

- Improves appliance efficiency

- Insulates the chimney

- Reduces and controls condensation

- Repairs interior deterioration

- Structurally strengthens

|